Pinch valves are widely used in various industrial applications. They are complete bore type of control valve. There is no blockage to move passage. These sort of valves are preferably suited for the handling of slurries, fluids with large quantities of put on hold solids.

They are used in systems that convey solids pneumatically. Pinch shutoff are straight action valves that can be used in both an off/ on manner or in throttling solution or in a variable placement. They are supposed to be the easiest in any kind of valve design. Pinch valves are used in various applications like are clinical, pharmaceutical, slurries, pulp, powder, pellets and wastewater.

Products used:

Stainless-steel

Cast iron

Carbon steel

Brass

Bronze

Plastic

Rubber

Steel etc.

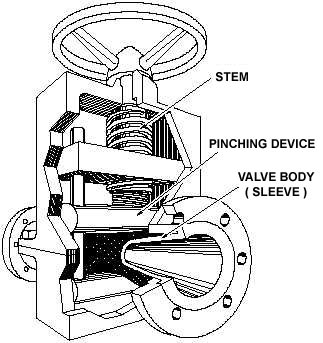

Parts of Pinch Valves:

Significant elements of a pinch valve are as adheres to:

Stem

Body (Sleeve).

Pinching tool.

The pinch shutoff consists of a sleeve and a pinching mechanism. The sleeve is the pinch valve body and made of such materials which are rust resistant.

How does a pinch valve runs?

Pinch valves are shut either by fluid actuation or manual methods. Electro-mechanical closure happens by actuating a solenoid, which in turn lowers a bar or gateway onto the sleeve, cutting off the circulation. With fluid activated pinch valves, the pinching activity is completed by air or hydraulic stress positioned straight on the elastomer sleeve. The pinch shutoff body functions as a built-in actuator, which gets rid of costly hydraulic, pneumatic, or electric operators. The pinch valve is shut mechanically with the motion of the pinch bars located on contrary sides of the sleeve.

Uses of Pinch Valves:

Pinch Valves assist in setup in grooved-end piping.

They offer placement indicator and also sound reduction.

They deal with hostile, particulate-laden liquids.

They appropriate for on/off fluid control applications.

Pinch Valve controls thick, corrosive and also abrasive liquids.

Pinch valves appropriate for high purity applications.

They are made use of for both automated and manual throttling.

They are used in the waste therapy plant.

They are useful in the handling of lime slurry as well as carbon-impregnated triggered sludge.

Pinch Valves are taken into consideration to be trusted, maintenance-free, affordable valves.

They are capable of taking care of the most abrasive, hard slurries, completely dry solids in process markets and corrosive chemical applications.

Pinch valves are made use of in various applications in wastewater and raw water applications.

They aid reduce maintenance costs in unpleasant solution.

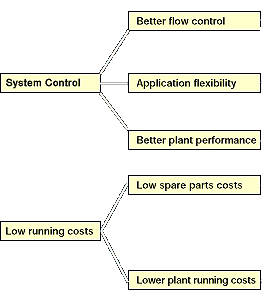

The following flow diagram will certainly give us a suggestion as to why should we utilize pinch valve:.

Aplications of Pinch Valves:.

Pinch Valves are simply suitable to fix all process issues which are associated with rough or harsh liquid handling in numerous locations like:.

Pulp as well as paper.

Mineral handling.

Food.

Power generation.

Chemical handling.

Effluent treatment.

Water and also wastewater etc

.