Operating a metal sheet laser cutting machine involves potential hazards, and it’s crucial to implement strict safety precautions to ensure the well-being of operators and maintain a secure working environment.

Here are some key safety precautions to consider when operating a metal sheet laser cutting machine:

- Operator Training:

- Ensure that operators receive comprehensive training on the safe operation of the laser cutting machine. Training should cover machine controls, emergency procedures, and safety protocols.

- Protective Equipment:

- Operators should wear appropriate personal protective equipment (PPE), including safety glasses or goggles with side shields, gloves, and closed-toe shoes. Additional PPE may be necessary depending on the specific machine and materials being processed.

- Machine Inspection:

- Conduct regular inspections of the laser cutting machine to ensure that all components are in good condition. Check for loose or damaged parts, and address any issues promptly.

- Ventilation and Fume Extraction:

- Implement effective ventilation and fume extraction systems to remove potentially harmful fumes and particles generated during the cutting process. Ensure that the work area is well-ventilated.

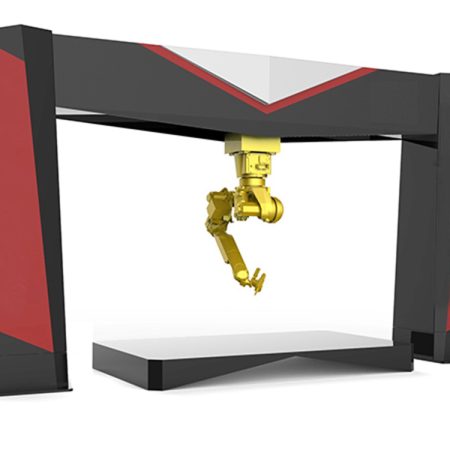

- Machine Enclosure:

- If possible, operate the laser cutting machine within an enclosed area to contain fumes and prevent access to unauthorized personnel. Enclosures also help protect operators from laser radiation.

- Emergency Stop Button:

- Install easily accessible emergency stop buttons on the machine. Operators should be familiar with the location of emergency stops and know how to use them in case of an emergency.

- Warning Signs and Labels:

- Clearly mark areas with warning signs and labels indicating potential hazards, emergency procedures, and safety guidelines. Ensure that operators understand and follow these warnings.

- Interlocks and Safety Features:

- Check that safety interlocks and features, such as beam shields and protective covers, are functioning correctly. These features are designed to prevent access to hazardous areas when the machine is in operation.

- Fire Safety:

- Have appropriate fire extinguishing equipment, such as fire extinguishers or fire suppression systems, in the vicinity of the laser cutting machine. China Metal Sheet Laser Cutting Machine suppliers Regularly inspect and maintain firefighting equipment.

- Secure Material Handling:

- Implement proper material handling procedures to prevent injuries. Ensure that materials are securely clamped or fixtured during cutting to prevent movement.

- First Aid Stations:

- Maintain a well-equipped first aid station in close proximity to the laser cutting machine. Ensure that operators are aware of its location and know how to access it.

- Regular Maintenance:

- Follow the manufacturer’s recommended maintenance schedule for the laser cutting machine. Regular maintenance helps prevent malfunctions and ensures the machine operates safely.

- Safe Power-down Procedures:

- Establish clear procedures for powering down the machine safely. Ensure that operators know how to shut down the laser and associated systems in an emergency.

- Proper Laser Alignment:

- Ensure that the laser beam is properly aligned to prevent accidental exposure. Follow the manufacturer’s guidelines for laser alignment procedures.

- Laser Safety Glasses:

- Provide laser safety glasses that match the wavelength of the laser being used. Operators should wear these glasses to protect their eyes from laser radiation.

- Supervision:

- Always have a qualified and trained operator present when the laser cutting machine is in operation. Supervision is crucial for prompt response to any issues or emergencies.

- Follow Local Regulations:

- Adhere to local regulations, standards, and guidelines related to laser safety. Familiarize yourself with any legal requirements governing the operation of laser cutting machines in your region.

- Emergency Response Plan:

- Develop and communicate an emergency response plan that includes evacuation procedures, contact information for emergency services, and steps to take in case of an accident.

By adhering to these safety precautions and guidelines, operators can reduce the risk of accidents and injuries associated with metal sheet laser cutting machines. Regular training, thorough documentation, and a safety-focused culture contribute to a secure working environment. Always follow the manufacturer’s recommendations and guidelines specific to the laser cutting machine in use.