Determining the appropriate crusher for your specific application needs involves several considerations, including the type and size of the filter press system, the characteristics of the filter cakes being produced, and the desired output size and capacity.

Here are some steps you can take to determine the appropriate crusher for your specific application needs:

- Evaluate the filter press system: Consider the type and size of the filter press system you are using, including the number and size of the plates, the operating pressure, and the filtration rate. This will help determine the appropriate crusher size and capacity.

- Determine the characteristics of the filter cakes: Consider the characteristics of the filter cakes being produced, including the material composition, moisture content, and consistency. This will help determine the appropriate crusher mechanism and settings.

- Determine the desired output size and capacity: Consider the desired output size and capacity of the crushed filter cakes, as well as any downstream processing requirements. This will help determine the appropriate crusher design and configuration.

- Consult with a crusher supplier or manufacturer: Consult with a crusher supplier or manufacturer to determine the best crusher design and configuration for your specific application needs. They can provide guidance on factors such as crusher type, size, capacity, and settings, as well as any additional features or customization options.

Overall, determining the appropriate crusher for your specific application needs requires careful consideration of the filter press system, filter cake characteristics, and desired output size and capacity. Consult with a crusher supplier or manufacturer to ensure that you select the best crusher for your specific application needs.

What is Vertical filter cake crusher?

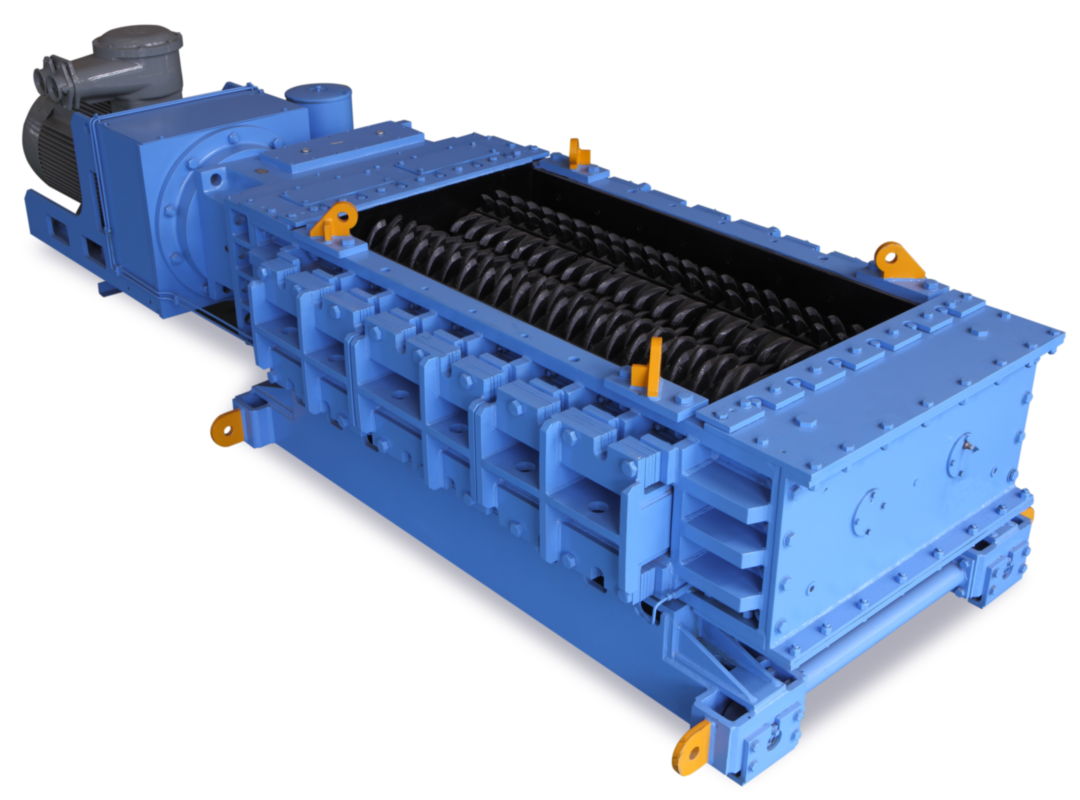

A vertical filter cake crusher is a device used to crush and reduce the size of filter cakes produced by a filter press system. Filter cakes are formed when solids are separated from liquids in a filter press, and can be difficult to handle and dispose of due to their size and consistency. China cake breaker factory A vertical filter cake crusher solves this problem by breaking down the filter cakes into smaller pieces that are easier to handle and dispose of.

The operation of a vertical filter cake crusher typically involves the following steps:

Positioning the filter cake: The filter cake is positioned vertically in the crusher chamber, typically using a hydraulic cylinder.

Crushing the filter cake: The crusher mechanism is activated, which applies pressure to the filter cake and breaks it down into smaller pieces.

Discharging the crushed filter cake: The crushed filter cake is discharged from the bottom of the crusher chamber, typically using a screw conveyor or other discharge mechanism.

Vertical filter cake crushers are commonly used in industries such as mining, chemical processing, and wastewater treatment, where large quantities of filter cakes are produced and need to be handled and disposed of efficiently.

They offer several benefits, including:

Improved handling and disposal: By reducing the size of filter cakes, a vertical filter cake crusher makes them easier to handle and dispose of, reducing the risk of spills and accidents.

Increased efficiency: A vertical filter cake crusher can help improve the efficiency of a filter press system by reducing downtime associated with handling and disposing of filter cakes.

Cost savings: By reducing the size of filter cakes, a vertical filter cake crusher can help reduce disposal costs, as well as reduce the need for additional equipment and labor associated with handling and disposing of filter cakes.

Overall, a vertical filter cake crusher is a useful device for improving the efficiency and effectiveness of a filter press system. Consult with a filter press supplier or manufacturer to determine the best crusher design and configuration for your specific application needs.