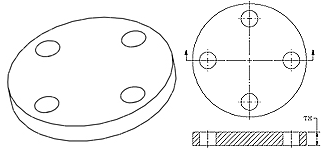

A popular group of pipe flange is the blind flange. A blind flange is made use of to close ends of piping systems. It is a kind of round plate without center hold but with all the correct screw holes. This blind flange is readily available in various sizes and also materials as well as is used to give favorable closer on completions of pipelines, valves or tools nozzles.

This flange aids in very easy access to a line once it has been sealed. The blind flange is sometimes custom made or machined to approve a small sized pipe to which reduction is being made. This reduction can be a threaded decrease or welded decrease.

Purchasing Tips

Specific factors that customers should take into consideration before purchasing blind flanges are as adheres to:

Dimension

Kind

End Type

Style

Length

O.D.

Pressure Rating

Density

Mass

. Products (examined for deterioration immune).

Examined and verified for accuracy, durability and accuracy etc

.

Materials used:. Some materials used in the manufacturing of blind flanges are as complies with:.

Stainless Steel.

Nickel Alloy.

Titanium.

Carbon Steel.

Cast Iron.

Brass.

Bronze.

Steel.

Aluminum.

Polypropylene.

Silicone.

PVC and so on.

Features of blind flanges:.

Some essential attributes of blind flanges are as adheres to:.

Blind flanges are in some cases provided with NPT fittings which allow stress test connections to be fitted.

Blind Flanges.

They are utilized to blank off completions of pipeline.

They are also utilized to blank off completions of shutoffs as well as stress vessel opening.

Considering factors like interior stress as well as screw loading, blind flanges, especially in the bigger dimensions, are the most very stressed out of all types of flanges.

Considering that the maximum emphasizes in a blind flange are bending tensions at the facility, they can securely be enabled to be greater than in various other types of flanges.

Blind flanges are made to fit common pipes in all sizes.